My workshop travel is finally winding down; I hope that means I’ll be finding more time to write this blog. A lot of the posts I write are for the benefit of my students. I try to expand upon (or repeat) information I’ve shared in workshops so the information will be available when their memories of the workshops have faded. From the responses I’m getting it appears that a lot of other people are finding the information useful as well. I’ll try to do better at keeping it up.

For those of you who don’t know, “caning” refers to the process of constructing a polymer clay cane. It has nothing to do with preserving fruit. People often ask why I recommend certain tools for my caning workshops; here are some of the reasons.

For those of you who don’t know, “caning” refers to the process of constructing a polymer clay cane. It has nothing to do with preserving fruit. People often ask why I recommend certain tools for my caning workshops; here are some of the reasons.

I prefer to use a glass work surface because it is transparent and it is more resistant to scratches than plastic. I also like the weight.

I place a plastic quilting grid under the glass to facilitate measuring and lining up pieces of clay. The grid has 1″, 1/4″ and 1/8″ divisions.

In addition to the usual slicing blade I carry an 8″ floor scraper blade. I use this blade for scraping/lifting larger sheets of clay off the work surface if my regular blades aren’t long enough. It works best when the sheet is lifted using a swift, continuous pull of the blade. Look for the blades in your home building supply store. There are many brands. The blades come packaged individually or in multiples.

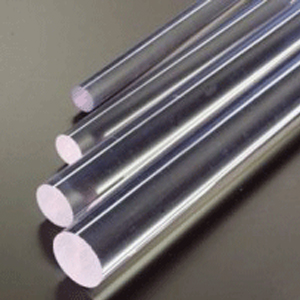

I have an acrylic roller that measures about 12″ long by 2″ in diameter. I find that much narrower rollers are more likely to leave indentations in the clay. This larger roller is particularly useful for reducing a rectangular cane. Rolling over the top of the cane helps even up the surface and square up the corners in addition to elongating the cane. Roll over one side of the cane , then flip the cane 1/4 turn to roll over the next side.

I also have a set of narrower rollers that I use to shape portions of a complex cane during construction. It is easier to insert a new component cane if the “receiving” area of the master cane has already been shaped to “accept” the component cane. I use my acrylic rollers and rectangles to do this shaping. The rollers are in matching pairs and range in diameter from about 1/4″ to 1″.

I also have a set of narrower rollers that I use to shape portions of a complex cane during construction. It is easier to insert a new component cane if the “receiving” area of the master cane has already been shaped to “accept” the component cane. I use my acrylic rollers and rectangles to do this shaping. The rollers are in matching pairs and range in diameter from about 1/4″ to 1″.

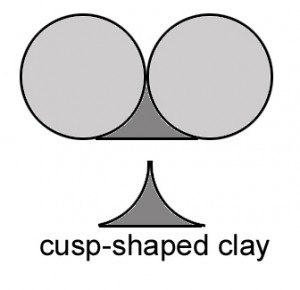

Used in pairs, the rollers are perfect for forming “cusp-shaped” units of clay to fill in the gaps between cylindrical components. The filling keeps the round components from turning into square components when the master cane is reduced.

![]() When it is necessary to join the edges of two sheets of clay together (as when preparing clay for a Skinner blend), I place a deli sheet over the position of the seam and burnish (rub) the surface of the sheet gently with a bone folder (above) or the back of a spoon to close the seam. I do this every time I start a Skinner blend to make sure the pieces won’t split apart when the sheet is folded and fed into the pasta machine.

When it is necessary to join the edges of two sheets of clay together (as when preparing clay for a Skinner blend), I place a deli sheet over the position of the seam and burnish (rub) the surface of the sheet gently with a bone folder (above) or the back of a spoon to close the seam. I do this every time I start a Skinner blend to make sure the pieces won’t split apart when the sheet is folded and fed into the pasta machine.

I find a pair of acrylic rectangles extremely useful for squaring up square canes and helping to shape triangular ones. I place them on opposite sides of the cane and press. The plastic should be thick enough that it doesn’t bow when you press against it. I have my basic set that I use most often, two rectangles approximately 3″ x 12″ x 1/4″, as well as some larger ones for working on larger canes. A single rectangle can be used to elongate and even out cylinders of clay (“snakes”) by rolling the cylinder of clay back and forth under the rectangle while pressing gently on the rectangle. Press too hard and the cylinder can come apart in the center and “deflate” like a flat tire.

I find a pair of acrylic rectangles extremely useful for squaring up square canes and helping to shape triangular ones. I place them on opposite sides of the cane and press. The plastic should be thick enough that it doesn’t bow when you press against it. I have my basic set that I use most often, two rectangles approximately 3″ x 12″ x 1/4″, as well as some larger ones for working on larger canes. A single rectangle can be used to elongate and even out cylinders of clay (“snakes”) by rolling the cylinder of clay back and forth under the rectangle while pressing gently on the rectangle. Press too hard and the cylinder can come apart in the center and “deflate” like a flat tire.

A steel potter’s rib is nearly irreplaceable when it comes to lifting up very thin sheets of clay without tearing them. I store my sliced canes between sheet protectors and sometimes these very thin slices are quite difficult to remove, especially when they have been stored for some time. A steel potters rib will often do the trick. Get the kind that is flat and has one straight edge.