I know some of you aren’t quite ready to pay the registration fee for a workshop and are tracking the number of remaining openings so I will be updating the table at the right with each post.

I know some of you aren’t quite ready to pay the registration fee for a workshop and are tracking the number of remaining openings so I will be updating the table at the right with each post.

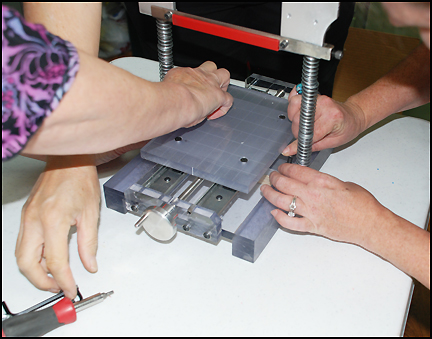

The slicer is now out and in use in the polymer clay community. About 12 people have them.

We still have quite a bit of documentation to complete on how to assemble it, maintain it and use it safely, so at this time we are only selling to people who have seen a demonstration and had a chance to use the slicer under our direction.

Testing it out in my workshops has been extremely helpful and has led to several improvements.

We are currently taking a couple months off from production to complete the improvements and enhance the safety features of the machine, as well as to work on the documentation. We are in the final stages of the patenting process, which has taken up quite a bit of our time (and money) as well. (For the purpose of the patent we changed the name of the slicer to the “Simmons Polymer Clay Slicing System.”)

When the latest improvements have been completed and all of the documentation is ready we will start distributing to people on the list who haven’t actually used the slicer, in the order their names appear on the list. At the rate things are moving this could be several months from now, but it will happen.

Please understand that this is a part time effort for us and is not producing a profit, just an hourly wage for Craig. If you are on the slicer list we will be contacting you to see if you are still interested in buying one. We will give you an estimated delivery date and request a $200 deposit to confirm your order. With recent improvements, the current price of the slicer is $850 (as of July 2012) plus $40 for shipping and handling. This includes a spare blade.

People have asked if we could make a smaller, less expensive version of the machine. We originally set out to do that, but weren’t able to achieve the level of precision and flexibility that I wanted at that scale, so we decided to build this larger machine first. Eventually we would like to design a smaller version that could be produced by a manufacturing company at a lower cost. Right now each machine is meticulously crafted by hand.

People have asked if we could make a smaller, less expensive version of the machine. We originally set out to do that, but weren’t able to achieve the level of precision and flexibility that I wanted at that scale, so we decided to build this larger machine first. Eventually we would like to design a smaller version that could be produced by a manufacturing company at a lower cost. Right now each machine is meticulously crafted by hand.